Motorcycle manufacturing with tradition.

As a motorcycle arises: production and shipping in five steps.

BMW Motorrad is the only manufacturer that offers its customers wide-ranging possibilities for the individual configuration of the motorcycle. In the motorcycle world we offer an unique "Customer-Oriented Sales and Production Process" (COSP) which is tuned to deliver the desired customized model to demanding motorcyclists. Hundreds order specifications can be changed flexibly until shortly before production starts.

The lead-plant of the international production of BMW Motorrad with its 230.00sqm is located in Berlin, in the district of Spandau.

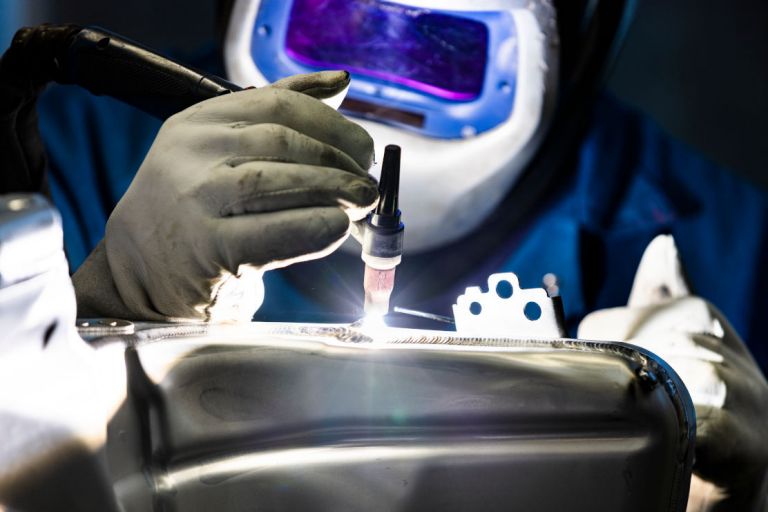

Mechanical manufacturing: Precise backbone.

Motor housing, cylinder heads, crankshafts and connecting rods as well as frames, tanks and chassis components: In the mechanical manufacturing the core components of the engine occur.

The computer-controlled machining centers guarantee a highly flexible and thereby precise mechanical manufacturing the components. The use of experienced and qualified staff and modern machine tools and measuring machines ensures best quality.

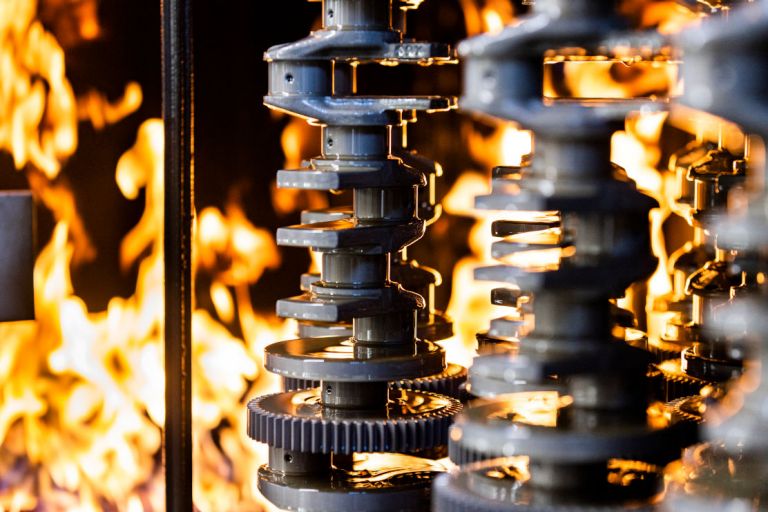

Motor mounting: marriage to the heart.

Highly flexible assembly systems with integrated testing technology are the key of the BMW engine assembly. From over 600 different small parts and components high-performance engines with two (Boxer), four or six cylinders are assembled. The employees are supported by numerous automatic stations during the assembly. The installation of a boxer engine takes about 90 to 130 minutes that the straight-six about 150 minutes to complete.

Paint: range of possibilities.

Computerized robots paint the motorcycle parts in up to 160 different shapes with water-based paints in more than 25 shades. The paint shop is designed so that the robot can paint parts of different size and geometry in no particular order. But often experienced colleagues are needed, especially when applying the traditional pinstripes and when applying the tapes on fuel tanks and side panels.

Assembly: The custom-made perfection.

To assemble the bikes they are mounted on a flexible transportation system. During the assembly process up to 150 different steps have to be passed. At each station the conveyor system adjusts itself automatically to the individual and ergonomically ideal working height for the employee. All job-related data and tightening torques and settings are automatically transferred to the respective assembly station. Until the 2,000 parts and components to a running order BMW Motorrad completes elapse depending on model 220-360 minutes.

Shipping: safe and sustainable.

Even in the finish area is carried out to prepare the BMW motorcycles for the journey to the customer. For the transport in the main European markets recyclable, foldable steel packaging is used. After the overseas transport takes place in stable transport containers made of wood and cardboard. Sustainability and logistical efficiency decide if the motorcycle is transported the way from our Berlin plant to the customer by truck, train or cargo ship.